The improper slag carryover from the steel ladle to the tundish promotes the accumulation of this material in the tundish, as well as causing corrosion and greater wear of the refractory. To avoid further damage, the number of heats per sequence is limited. Hence, due to the decrease in the number of heats, the remaining steel inside the tundish represents a reduction in metallic yield, and conversely, increase the cost of production. In addition, when slag reaches the final product, it accumulates in inclusions that directly affect product quality.

Therefore, to achieve positive results during the process, slag carryover control is necessary, and in this study, the slag detection system proved to be a tool capable of reducing the timing of slag carryover from the ladle the tundish in 8.6 seconds, when compared to the traditional detection method.

Slag detection: traditional method x detection system

Aiming to increase the metallic yield and the final product quality, a Tozato customer hired the slag detection service.

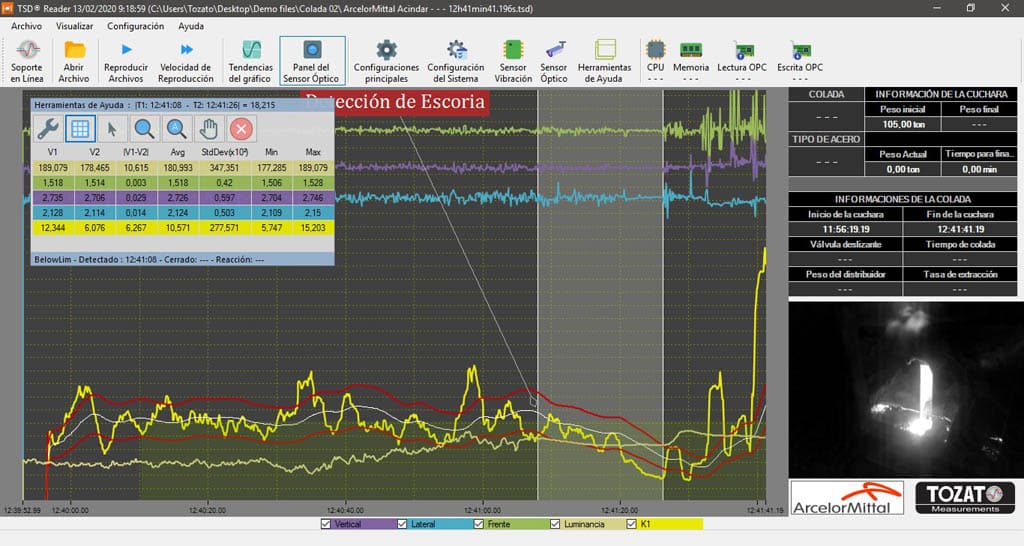

In one of the tests performed, an interval of 15.3 seconds was verified between the moment when the system detects the slag carryover and the moment when the operator manually closes the slide gate as it can be seen in Picture 1.

Picture 1: Moment of slag detection by the system (15.3 seconds before the flow is stopped).

The red circle in Picture 1 highlights the moment when the ferrostatic pressure in the ladle decreases. The operator, unaware of the start of the slag carryover, instead of closing the gate, opens it further, pouring more slag into the tundish and thus increasing the layers deposited in the container.

In another case, the time between the detection of the slag carryover through the system and the closing of the slide gate was even longer. The slag / steel flow until the gate shut down was 18.6 seconds as can be seen in Picture 2.

Picture 2: Moment the system detects slag (18.6 seconds before the flow is stopped).

In this second case, there is an increase in the slag pouring time in relation to the first, which indicates that without a precision tool, the operator is subject to a great variation in the reaction time for closing the gate.

Thus, based on the slag detection system used in this study, Table 1 created with the records of the operator’s reaction times for closing the ladle, and the referred amount of slag and steel poured into the tundish in tons, at an average extraction rate of 105 ton/h.

|

Record |

Reaction Time (seconds) |

Extraction Rate (ton/h) |

Slag + Steel (ton) |

|

1 |

15.60 |

105 |

0.455 |

|

2 |

1.80 |

105 |

0.053 |

|

3 |

18.60 |

105 |

0.543 |

|

4 |

8.10 |

105 |

0.236 |

|

5 |

4.30 |

105 |

0.125 |

|

6 |

3.60 |

105 |

0.105 |

|

Average |

8.60 |

105 |

0.250 |

From the data presented in Table 1, it is possible to conclude that the average reaction time of the operator, after the detection of the slag by the system is 8.6 seconds. Therefore, considering the average extraction rate of 105 ton / h, it is estimated that a surplus of approximately 250 kg of slag and steel will be poured from the ladle to the tundish per heat.

Benefits of the slag carryover control

It is worth mentioning that the increase in metallic yield and product quality are the main benefits sought by this customer with the use of the slag detection system. It is important to note that it is necessary to have a balance between yield and quality in order to assess the amount of slag that is acceptable in the tundish. In addition, the following benefits are observed:

- Operational Benefits

- Increased Metallic Yield

- Increased Tundish Service Life

- Increased Shroud Service Life

- Greater Safety for Operators

- Increased Product Surface and Internal Quality

Operational Benefits

The accumulation of slag in the tundish requires undesired process outages to slag off and prevent it from reaching the final product. Then, the detection of the slag carry over by a precision tool reduces the number of stops to slag off the tundish. Operationally, more heats can be done in a sequence.

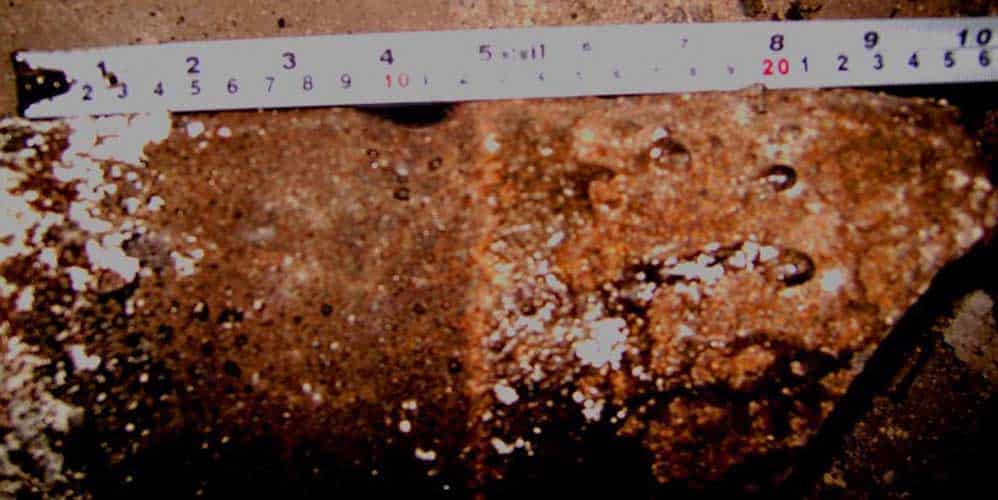

A great benefit for this client, since there was a deposit of 10 mm of slag per heat (Figure 3).

Picture 3: Typical accumulation of slag in the tundish that reaches 10 mm per heat.

Increased Metallic Yield

This customer closed the gate to prevent slag carryover when the ladle reached a certain average weight. The gate was often closed early. With the use of the slag detection system, it was possible to reduce the remaining steel, achieving savings of up to 1.2 tonnes per ladle, resulting in a substantial increase in metallic yield.

Increased Tundish Service Life

The reduction of slag poured in the tundish proportionally reduces the chemical and physical processes, corrosion and wear of the refractory and the components used to drain the tundish, as shown in Picture 4. Therefore, there is a possibility to increase the tundish service life.

Picture 4: Result of refractory corrosion and wear due to the accumulation of slag.

Increased Shroud Service Life

The accumulation of slag in the tundish causes wear on the shroud as the submerged part maintains constant contact with the metallic bath, which is possible to see in Picture 6. Therefore, the smaller accumulation of slag in the tundish causes less corrosion and, therefore, increases its service life.

Picture 5: Example shroud wear due to slag accumulation.

Greater Safety for Operators

Tundish breakouts, caused by the deposit of slag, represent a great danger for operators. However, when the amount of slag poured is less, the chance of corrosion perforations that may occur in the tundish is also reduced.

Increased Product Surface and Internal Quality

The greater the amount of slag remaining in the tundish, the greater the chances of the slag reaching the final product of the casting and agglomerating into inclusions, as it can be seen in Picture 6 and Picture 7. Its presence negatively affects the mechanical properties of the product, which can lead to the formation of cracks and downgrading. Therefore, the absence of slag represents a higher surface and internal quality of the product.

Picture 6: Surface and internal defects caused by slag inclusion in the final product.

Picture 7: Surface and internal defects caused by slag inclusion.

Conclusion

This paper points out that with the use of the slag detection system it is possible to reduce on average 8.6 seconds of material flow poured into the tundish, which corresponds to approximately 250 kg of slag and steel and to have a gain in the metallic yield in 1.2 tons per heat.

In addition, with the reduction of the slag carryover, the accumulation that used to reach 10 mm of slag per heat will decrease proportionally. Therefore, in long term, it will be possible to observe the increase of tundish refractory service life, which will no longer potentially suffer the chemical attack by the oxides present in the slag. From an operational point of view, the number of heats per sequence will be greater, as the process will not need to stop to empty the slag boxes.

Finally, it is possible to conclude that there is no advantage in allowing the slag carryover from the ladle to the tundish, and the acquisition of a system capable of detecting the slag carryover in this step of pouring the liquid steel is a fundamental tool when it is desired to achieve higher quality and performance.