Irregular frequency of the oscillation table generated by a failure in the liquid steel leveling sensor causes a great loss to production, quality, and maintenance.

Steelmakers observed that product downgrading in steel mills can be associated with problems with the oscillation table in continuous casting machines.

As reported by a customer, the maintenance team was dealing with excessive machine’s downtime.

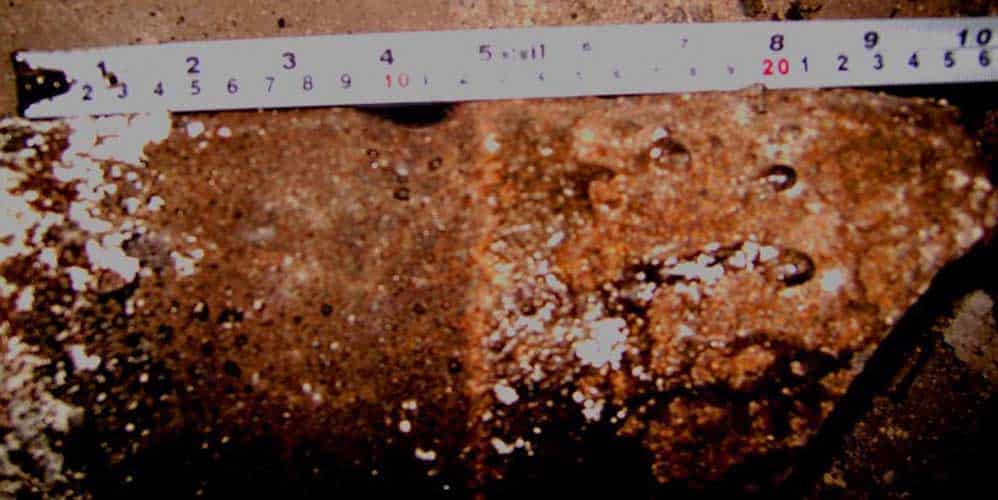

Continuous breakout incidents or other problems related to the oscillation table and the mold, which in turn also concurred with decreasing in product’s quality, which came to show cracks and lapses regularly.

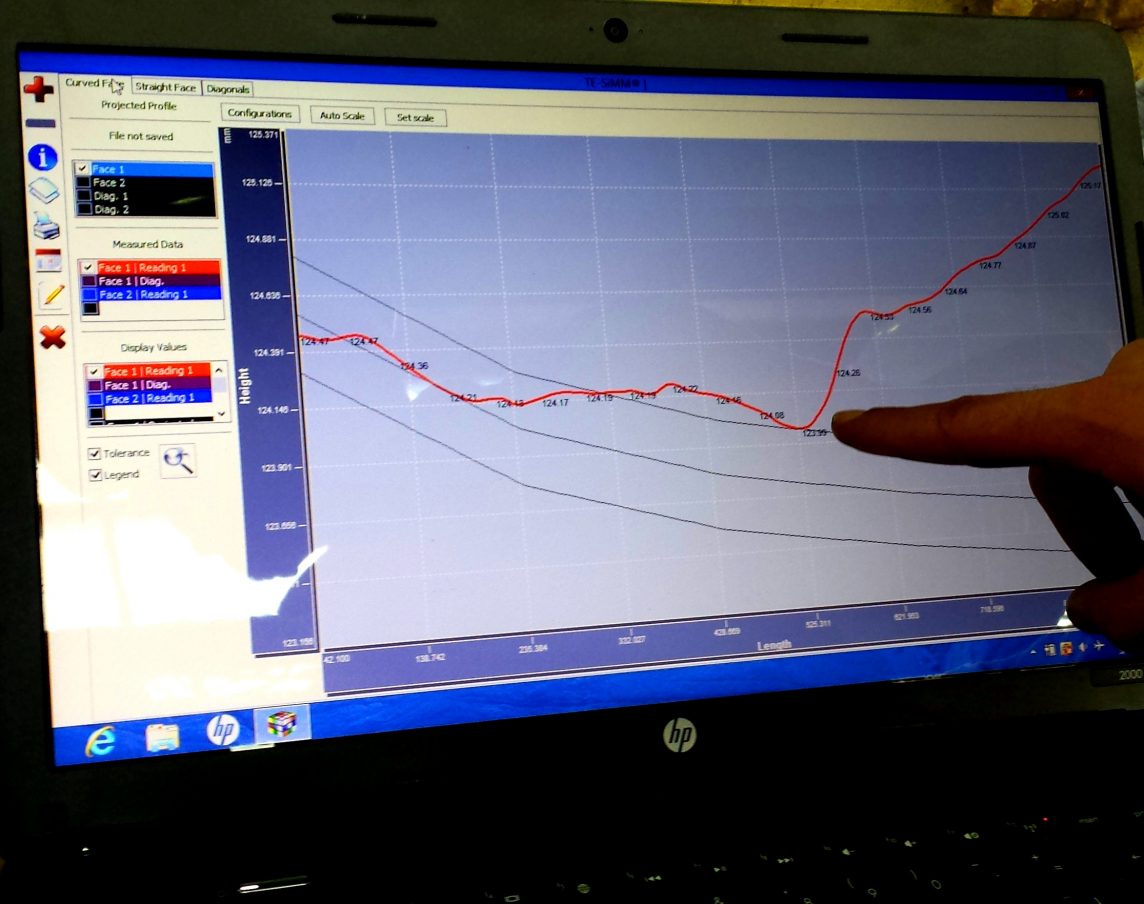

Picture 1: The picture shows the consequences of breakouts.

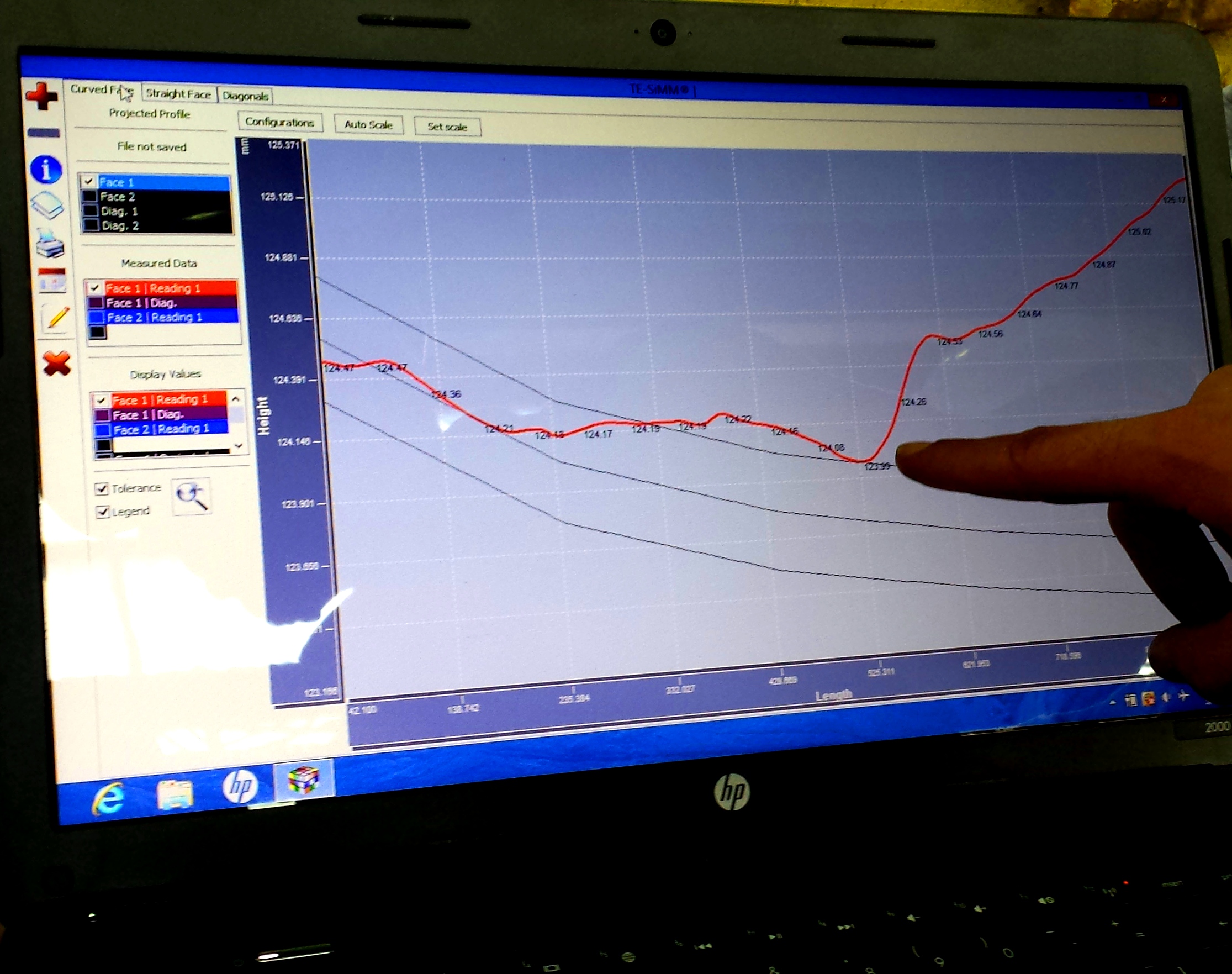

Picture 2: The picture shows cracks on both billet and bloom.

In order to investigate and solve the problems at the company, the customer contacted Tozato.

At the company’s request, Tozato’s engineering team traveled to the company to provide support and investigate the issue using a tri-axial sensor equipment, which analyzed the trajectory, vibration, and metallurgical conditions of the mold’s oscillator.

Frequency of the Oscillation Table’s problem detection and analysis

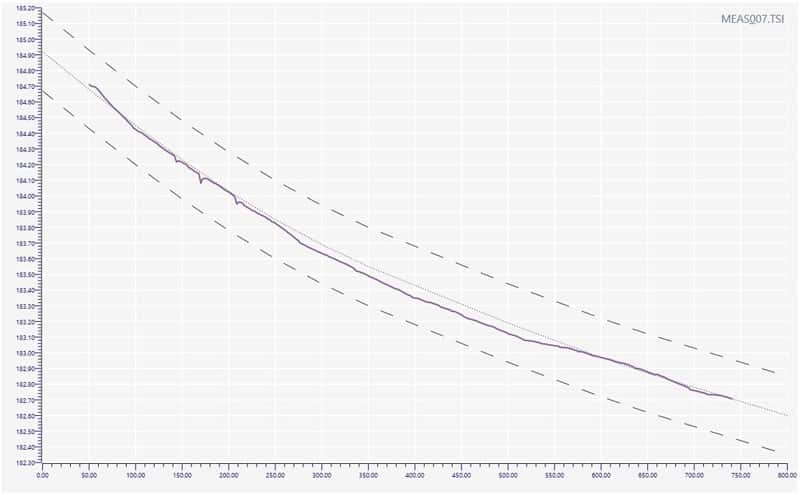

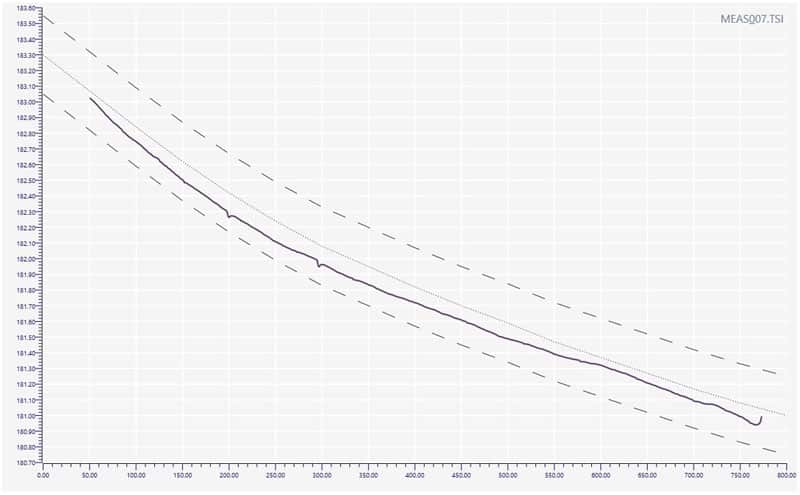

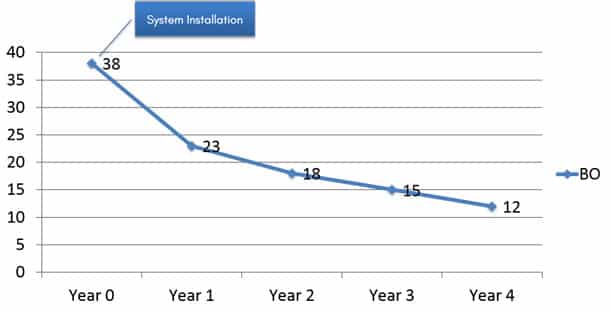

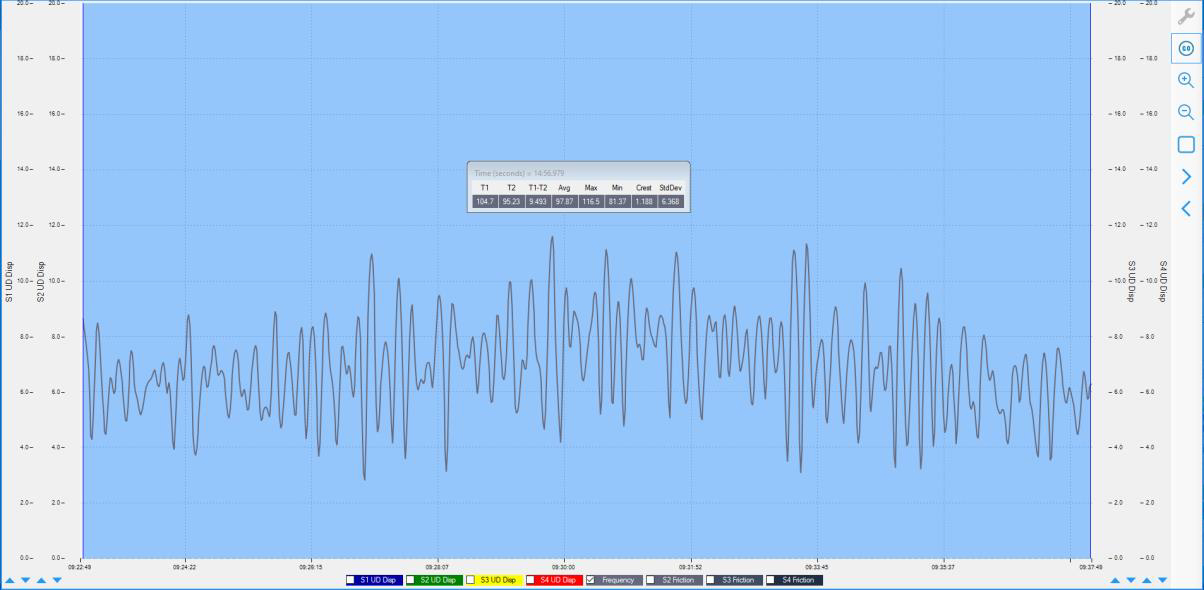

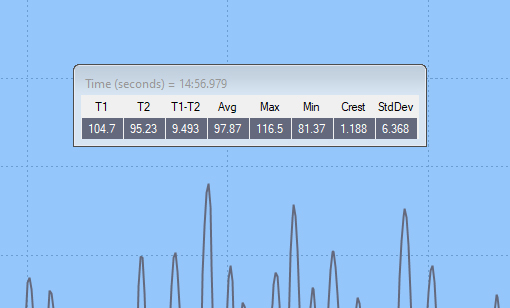

The problem was discovered after measuring the oscillation table with Tozato Measurements’ cutting-edge technology equipment. It was found that the oscillation table’s frequency was undergoing major changes (from 81 CPM to 116 CPM) in a matter of a few seconds.

This acceleration and abrupt reduction of frequency not only caused extra wear in the copper molds, but also resulted in constant breakouts in addition to causing product downgrading, forming severe cracks and recurring bleedings.

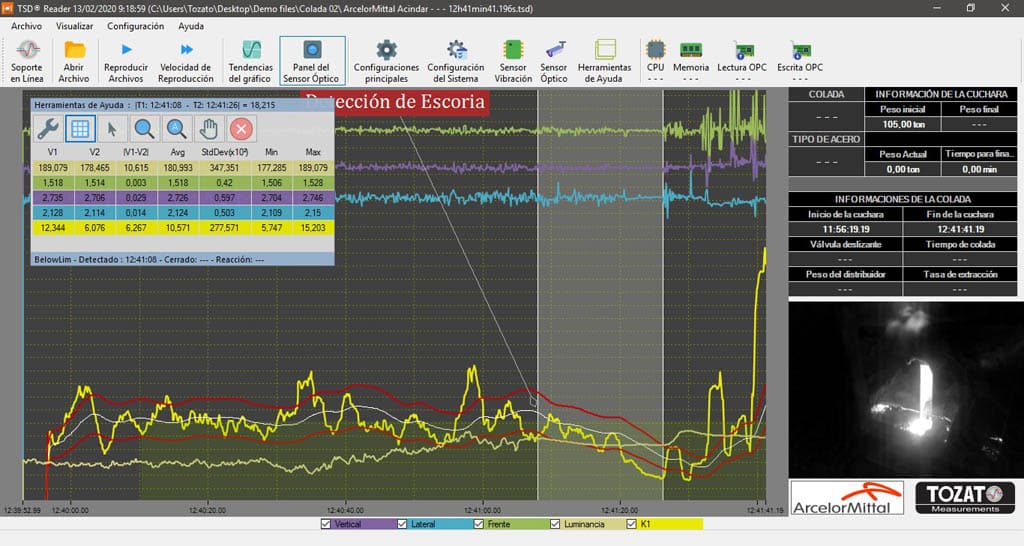

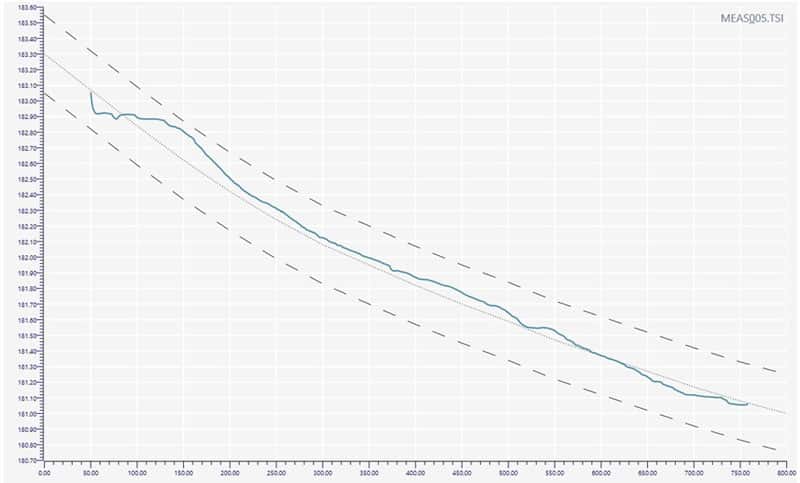

Picture 3: The picture shows irregular peaks of frequency of the oscillation table on the trend line.

The suspicion was that the high and rapid changes in the oscillator’s frequency were caused by the lack of calibration of the leveling sensor that assists in the distribution and volume of liquid steel within the copper mold.

Since it was without proper calibration, the motor was activated at the driver’s command to sometimes compensate the frequency, sometimes to reduce it.

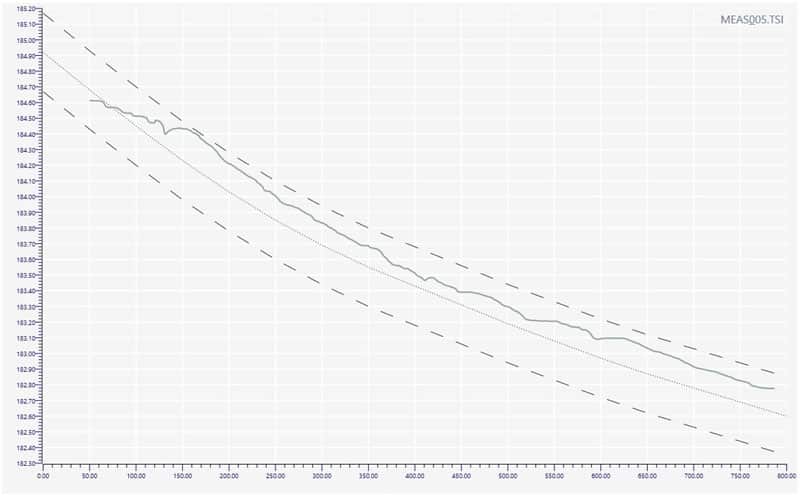

Picture 4: The picture shows, in the short period of exactly 14 minutes and 56 seconds, a variation of 81.37 CPM minimum and 116.5 CPM maximum.

It is common knowledge that the continuous casting machine operates from the motorized impulses which in turn assist the oscillation table and, at a steady frequency, provide high product quality. However, when there is a problem with the leveling sensor’s calibration, this frequency can change and cause major problems in the production and quality areas, as it was in this case with this customer.

Immediate solutions were provided by Tozato’s engineering team. After identifying the problem and confirming the diagnosis using the monitoring system, the company requested the installment of Tozato’s continuous monitoring equipment to control the mold’s oscillation table.

Conclusion

As a consequence of Tozato’s high precision and resolution equipment, the company was able to increase the production, so that the quality of these products was within the required standards, avoiding greater expenditures with maintenance and product’s downgrading, since the use of this system increased the mold’s and the oscillation table’s service life, acting against rhomboidity and ovality, in addition to proving to be efficient in drastically reducing the incidence of breakouts.