The link between deformation on the mold external surface and taper loss on its internal faces was unknown. The correlation between those two can only be noticed through a precise measuring equipment, which helps detecting internal anomalies, that happens to be millimetric.

The root cause for mold external surface deformity can be many, such as handling and transport errors and water jacket and screw assembling errors. Even though the copper mold presents a good mechanical resistance for its application, it can experience the consequences of those errors and present deformities. That way, when caused, those defects can lead to some several production problems, because once the taper is compromised, it is not possible to assure the proper steel skin formation.

[Case Study] Water Jacket Assembling Error

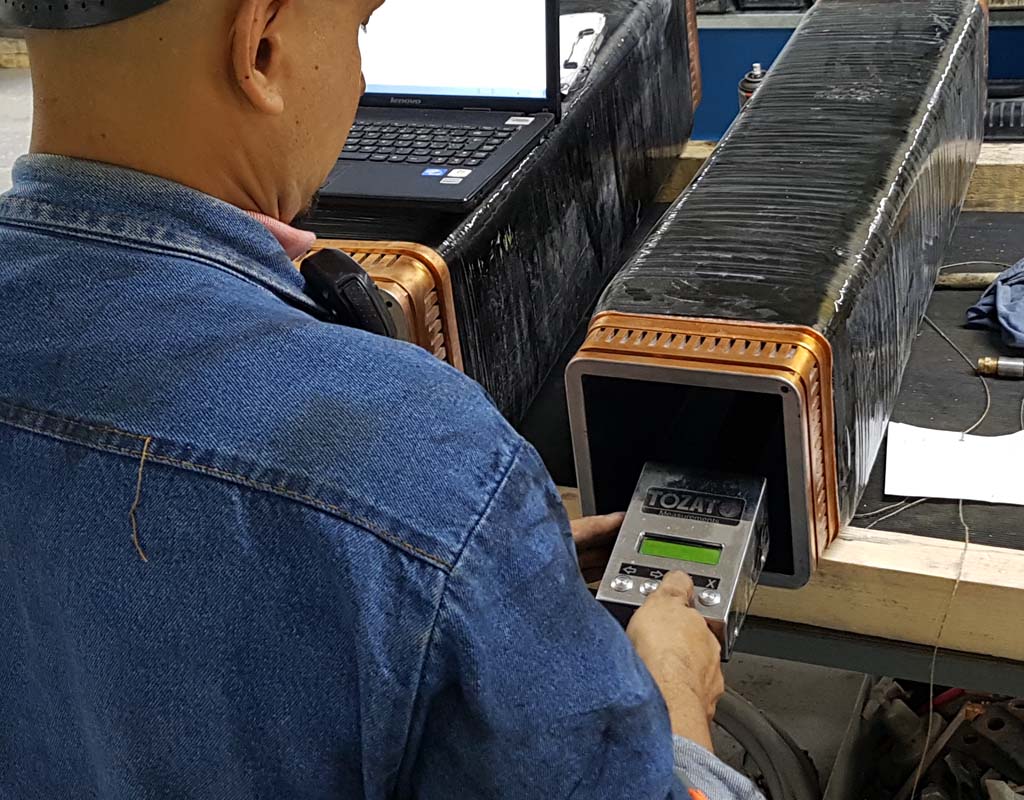

Recently a Tozato costumer identified an external surface deformity caused by a water jacket assembling error that ended up seriously damaging the taper on its interior. In this occasion, when proceeding with mold’s assembling in the jacket their screw got uncontrolled thigh up causing a warping on the external surface; As a consequence it constricted the interior face and caused taper loss.

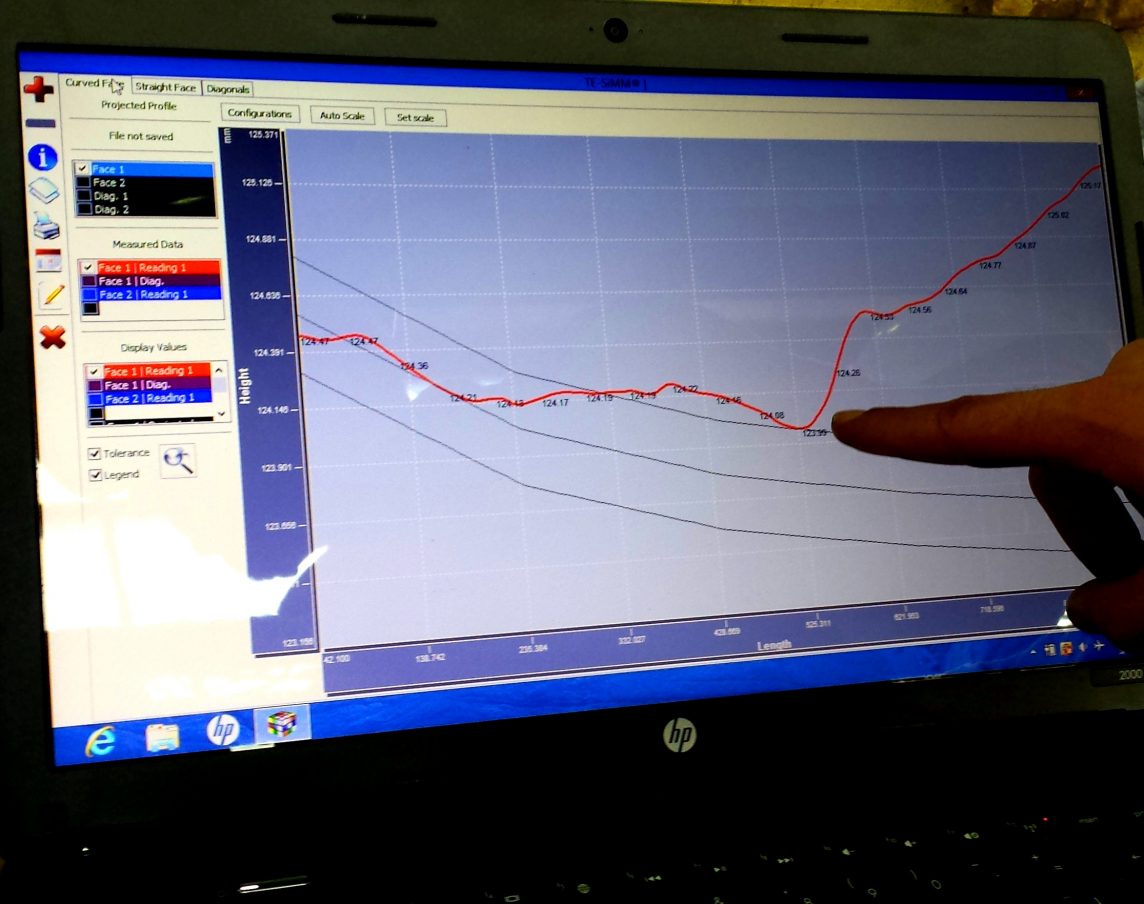

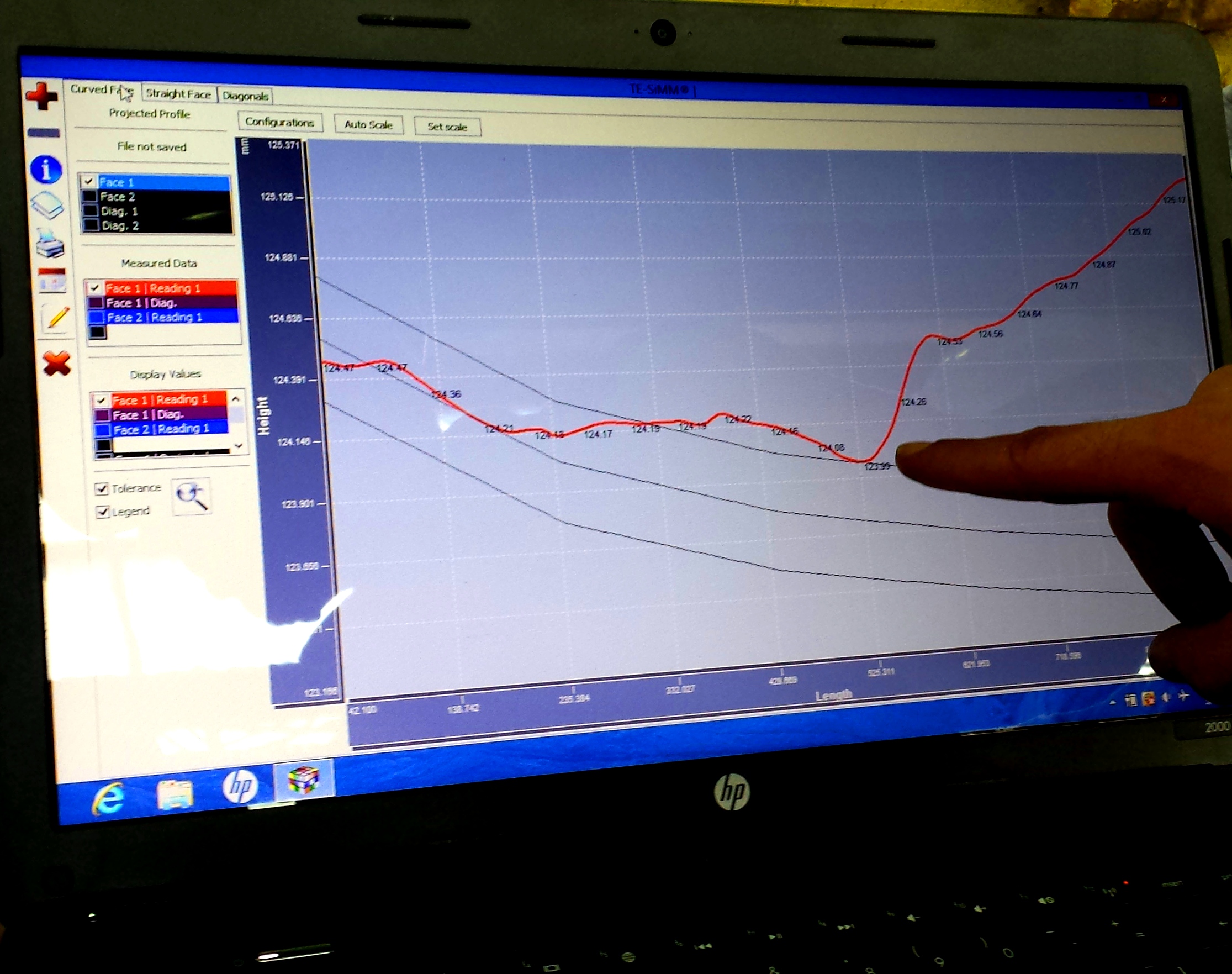

In picture 1, the two areas that were most affected by extreme screw pressing are pointed. It is also perceptible that the warping is extended through the mold following the same direction.

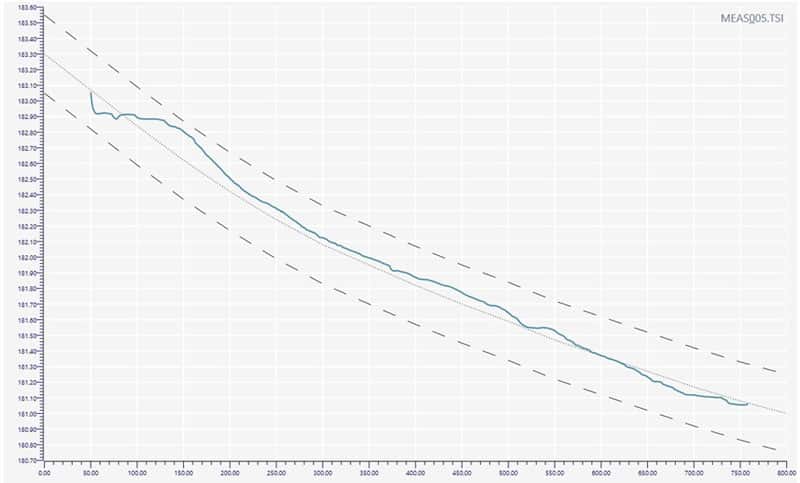

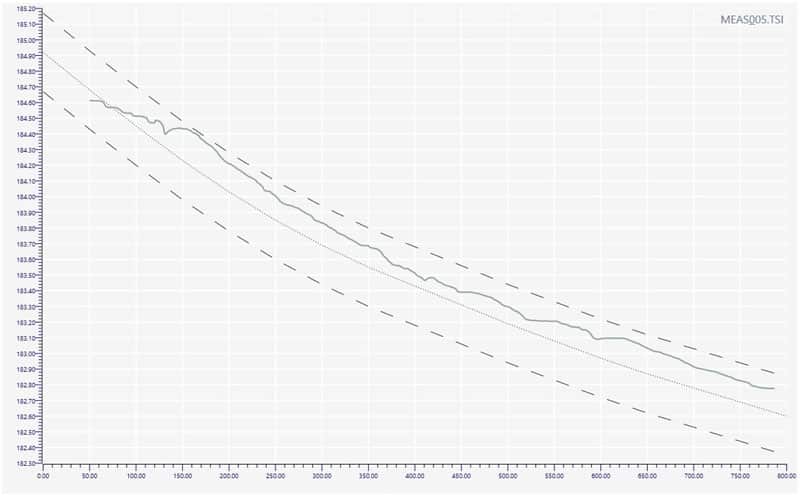

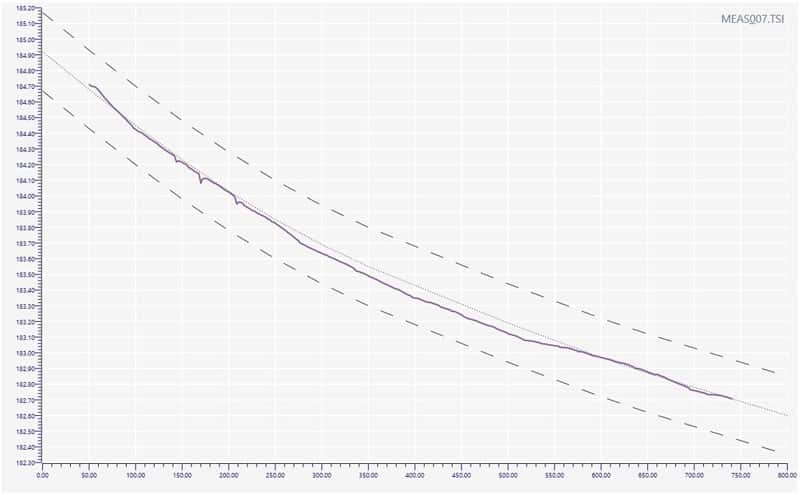

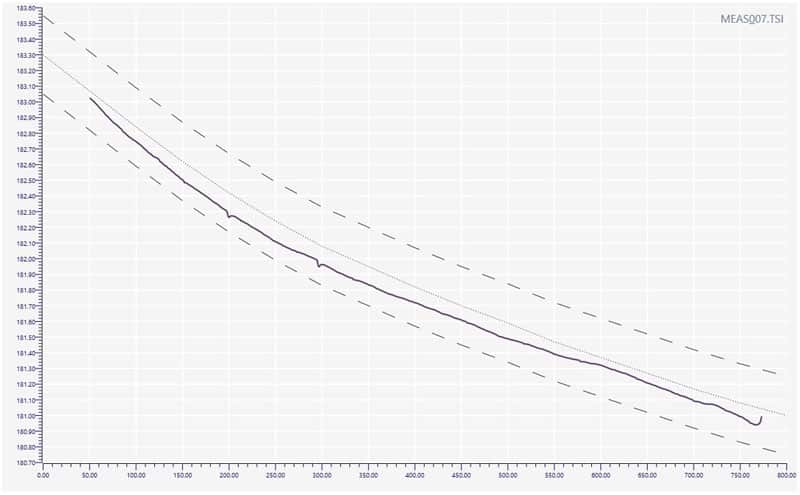

It is worth mentioning that, to a naked eye, the warp caused by the jacket screws did not indicate to have caused a taper damage. Only by utilizing a measuring equipment, it was possible to detect this deformity, which at first would have go unnoticed. That said, the mold’s measurements showed the following results:

In the picture above, a severe warp is identified in the area indicated in the graph, which was most damaged by the assembling error. Besides that, from this point on there is wear that goes all the way to the mold end.

Production Risks

Using out of specifications molds can lead to defects on product’s surface, such as cracks (which have the wrong taper as one of their listed causes), besides the possibility of bleedings and breakouts. With measuring results in hands, it was possible to conclude that this mold was not inside the expected profile; thereafter it could represent a risk to the production if not discarded.

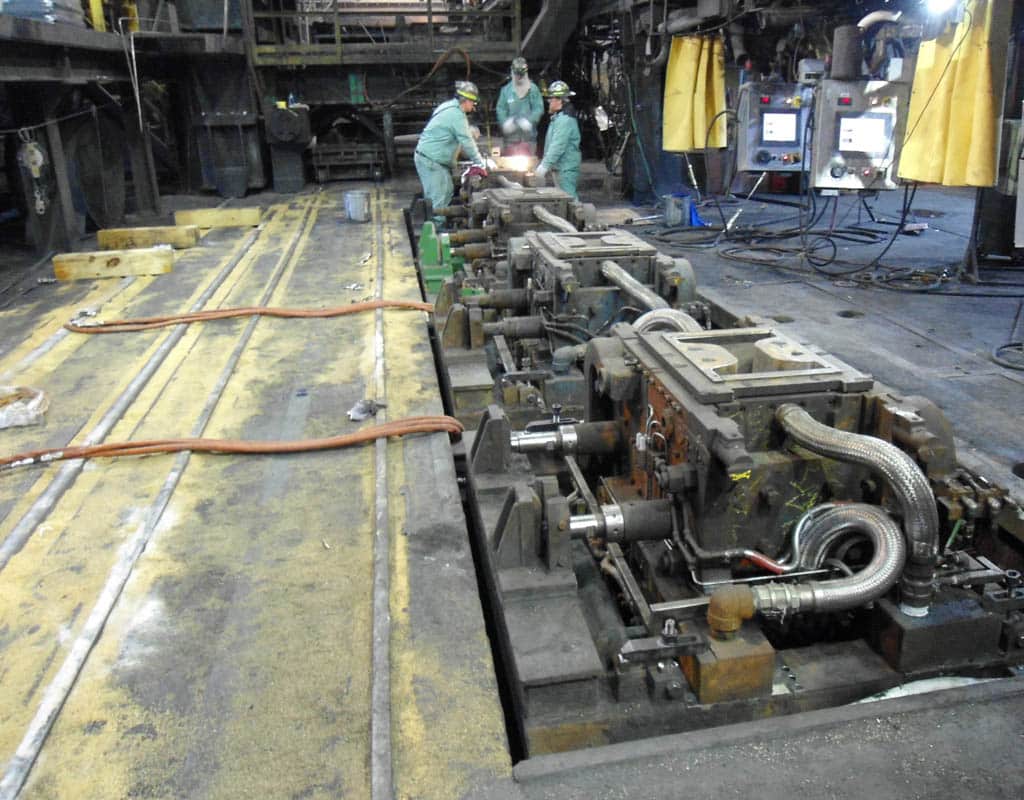

For example, product downgrading is one of the damage provoked by a breakout, as we can see in Picture 3: a thin steel skin that has ruptured during negative strip process due to ferrostatic pressure.

Conclusion

That said, it becomes evident the necessity to create a preventive maintenance culture, that utilizes precise technology like the ones provided by Tozato, aiming to avoid new and old molds improper use, considering the many disadvantage that can occur from the sum of this situation. The preventive maintenance will help to increase the mold’s service life, reduce the product defects, like cracks and breakouts, reduce machine downtime, as well as avoid the premature discard of the mold.