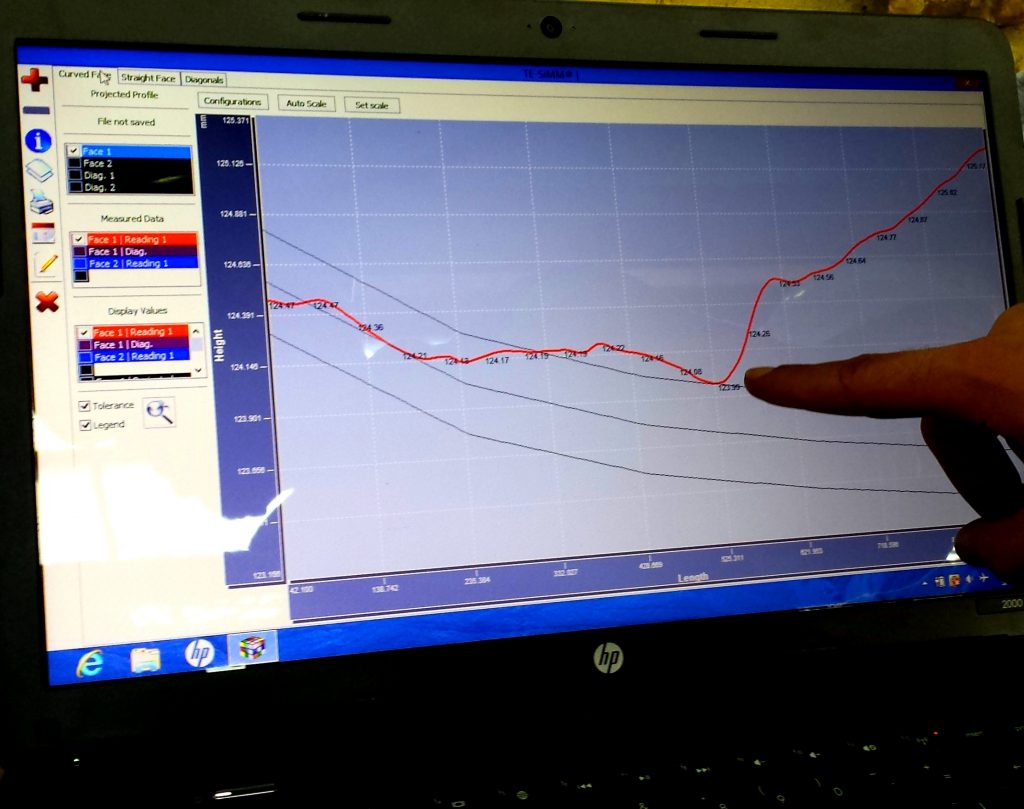

The Tozato Roll Alignment Checker is a lightweight, intuitive ,accurate, and easy-handle device, developed to take quick and reliable readings between the mold, foot rolls, and segment zero. Its high performance inclinometer based technology is capable of taking readings with 0.0004 in of accuracy, collecting data in seconds, and display them on an easy to use interpretative touch-screen interface.

READ MORE ABOUT TOZATO ROLL ALIGNMENT CHECKER

BENEFITS AND FEATURES

Through the use of this system, it’s possible to:

FAQ (Frequent Asked Questions)

How is the readings taken with the Alignment Checker?

The readings are taken with inclinometer contact sensors and the results are exhibited on the touch-screen display.

What is the system weight? Is it easy to carry?

The system is lightweight, compact and can be operated by one user, without need of crane.

How long does it take to measure the alignment?

The data is collected easily and instantly.