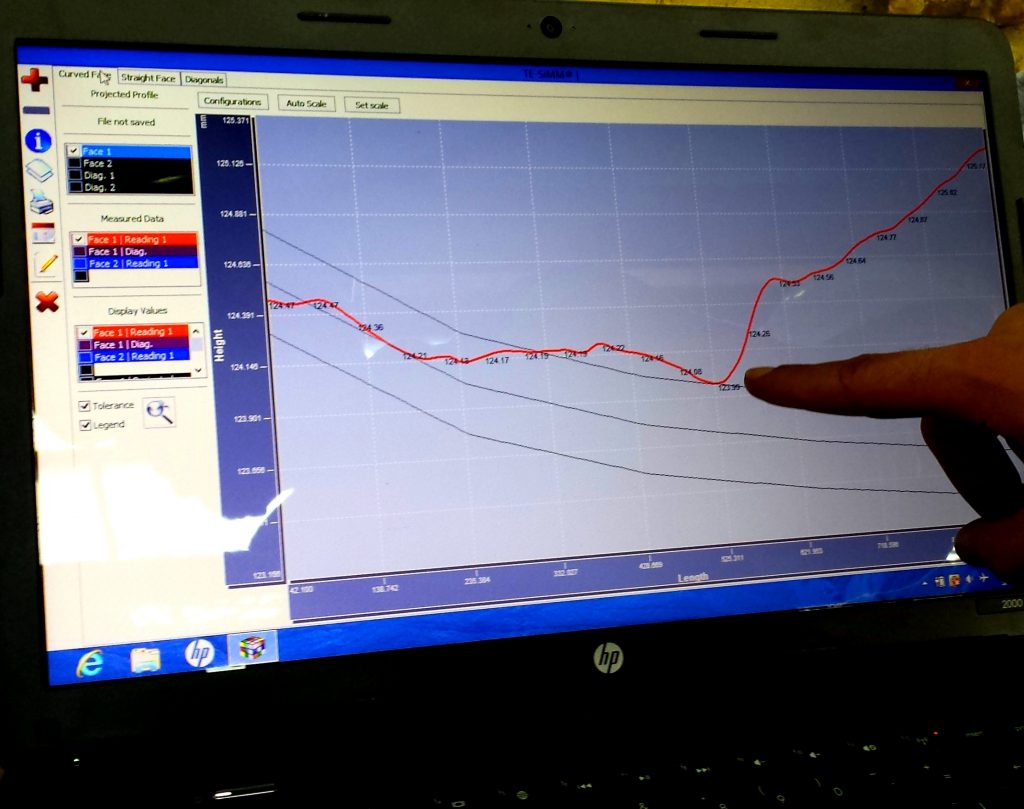

The Tozato Slag Detector, for continuous monitoring of metal teeming ladles, is equipped with a very sturdy software that uses a shielded vibration sensor and a high quality optical sensor, giving the system an unique performance in monitoring the slag carryover from the teeming ladle to the tundish.

The tri-axial vibration sensor has precision of ± 0.0005 in, acceleration of ± 0.0353 oz per direction, and it is combined to the optical photometric sensor that has a CCD matrix for high quality image capturing, UV coated lens, zoom and focus remotely controlled with low noise sensibility. The two sensors combined monitoring grants a high detection rate and low slag carryover rates from the steel ladle to the tundish with reliable metallic yield.

READ MORE ABOUT TOZATO SLAG DETECTOR

BENEFITS AND FEATURES

Through the use of this system, it’s possible to:

FAQ (Frequent Asked Questions)

How many sensors are used in this system?

The Tozato Slag Detector combines an optical photometrical sensor and a tri-axial accelerometer sensor, both with high performance that guarantee high slag detection ratio.

Does the system works with only one of those sensors?

Yes. However, the usage of only one sensor does not guarantee the system full potential and performance.

Are there different detection levels?

Yes! It is possible to set up the Tozato Slag Detector sensibility according to the production needs.