Tozato Taper Monitor/Checker are both equipments developed by Tozato Measurements to decrease breakout incidence ratio and increase product surface quality, through the control of narrow faces’ taper.

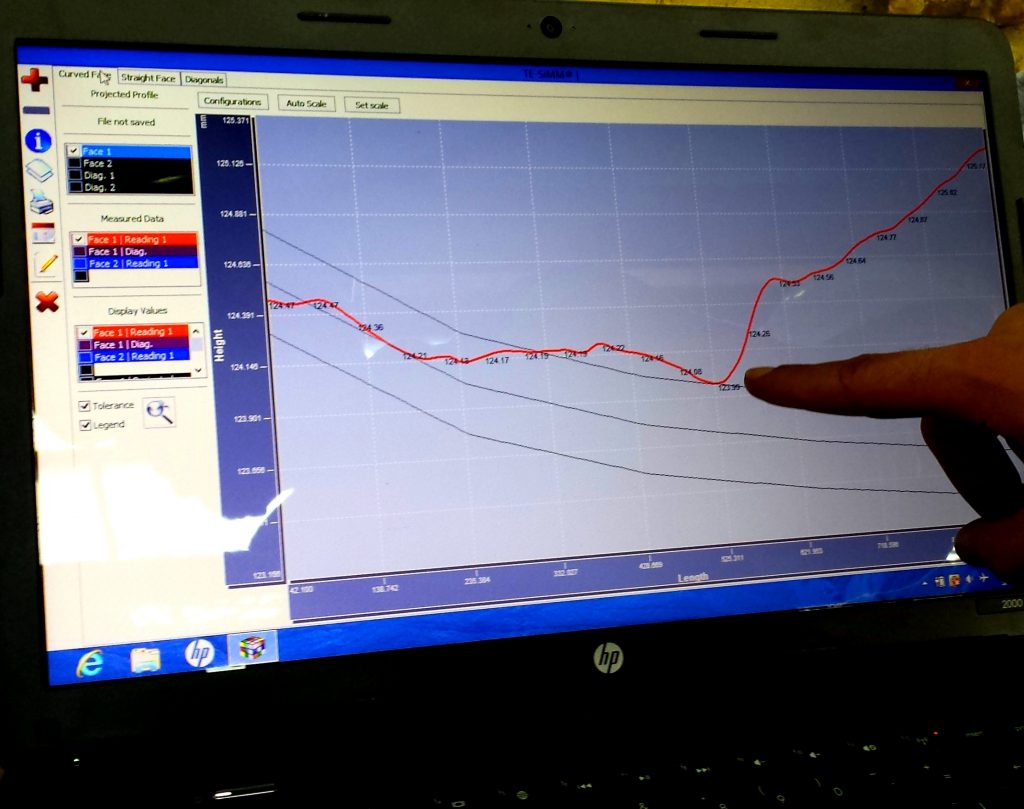

The permanent Tozato Taper Monitor system ensures real time and full control of the slab mold narrow faces’ taper. This equipment guarantees the narrow faces proper angulation and, thus, preventing production accidents such as breakouts and surface defects on the product. This is a care practice that allows a smarter use of maintenance resources.

The Tozato Taper Checker allows quick and safe readings of slab mold narrow faces taper. It is lightweight, hand held, easy-handle, operated through a touch screen interface. System equipped with hardware composed of high accurate inclinometer sensors (0.005°). It ensures proper readings on the narrow faces angulation, which is a safety practice that can prevent production accidents such as break-outs and product surface defects.

READ MORE ABOUT TOZATO TAPER MONITOR/CHECKER

BENEFITS AND FEATURES

Through the use of this system, it’s possible to:

FAQ (Frequent Asked Questions)

Is this a monitoring system or a Checker system?

There are two different systems: the Tozato Taper Monitor and Taper Checker. Therefore, the Taper Checker is an equipment designed to make spot readings, while the Taper Monitors is designed to monitor on real and full time the slab mold narrow faces taper.

How is the measurement done? Is it through any kind of software?

The system uses high accurate inclinometer in order to measure the slab mold narrow faces taper angulation. The permanent system version, Taper Monitor, monitors on real time the angle at cold and hot conditions. On the other hand, the Taper Checker makes spot measurements and the data are displayed instantly on the touch-screen system display.

What prevents the system from burning?

Thanks to the Tozato Measurements wide experience and know-how in sensors cooling, even in the casting area, the sensors temperature are kept around 40°C, which ensures its long service life.