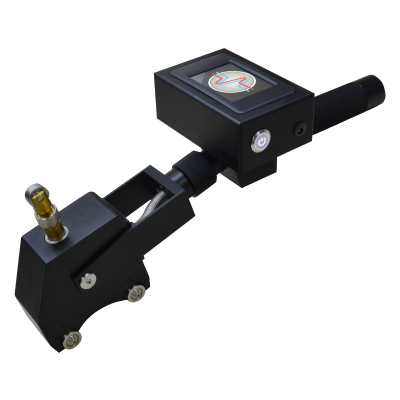

The Tozato Roll Gap Checker is a lightweight and ergonomic device that allows quick and accurate readings of segment rolls. Therefore, the system’s main goal is to detect problems such as alignment errors, rolls’ wear and warp. In addition, this device is equipped with a touch-screen controller interface that enables data collect instantly, as result, facilitating its use. On top of that, the system comes with a smart software, which enables graphical reports that can be stored and printed as well.

The system measures the roll gap with ± 0.0004 in of precision and, as a result, it is capable of diagnosis roll gap misalignment problems on new segments, and also abnormal gaps on refurbished segments. In conclusion, it’s a lightweight, self-adjustable, and easy-handle tool that allows continuous measuring in a quick and safe way.

READ MORE ABOUT TOZATO ROLL GAP CHECKER

BENEFITS AND FEATURES

Through the use of this system, it’s possible to:

FAQ (Frequent Asked Questions)

How long does it take to measure a full segment?

Each roll gap measurement is taken within a few seconds. Tozato Roll Gap Checker users have already reported a decrease of up to 95% on the time to measure the segments.

Can I measure more than one segment with a single equipment?

Yes. One equipment is capable of measuring all segments.

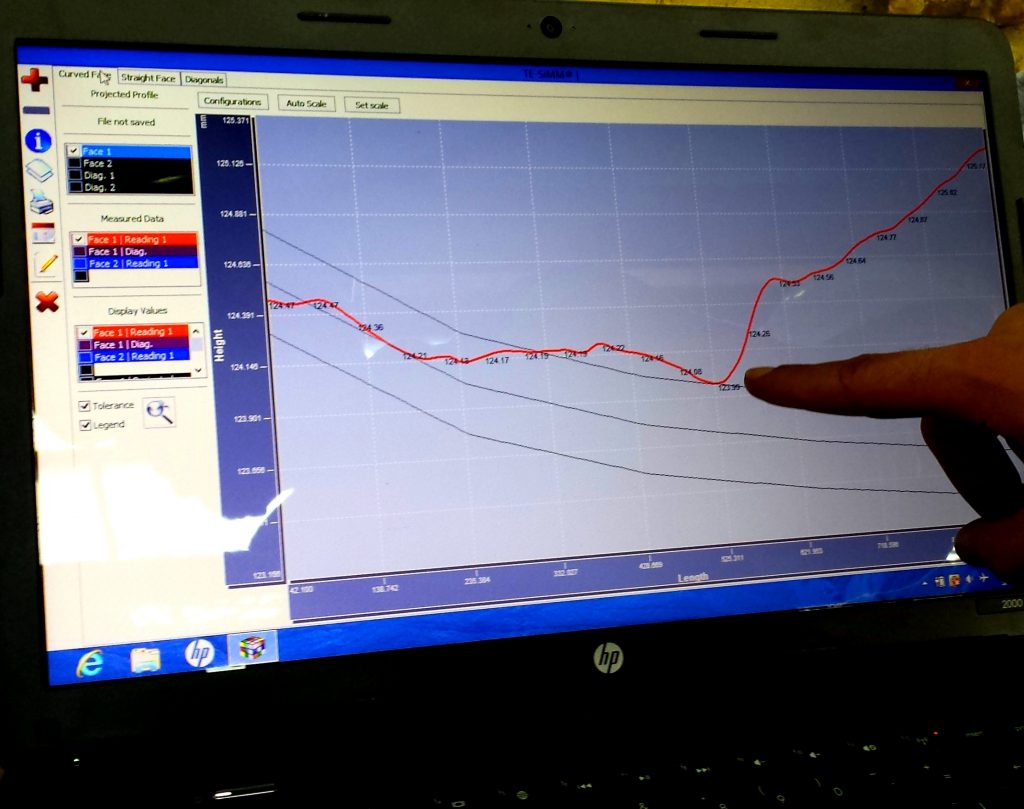

How the system display the results?

The data collects are displayed instantly on the touchscreen display. Furthermore, the data can be downloaded to the computer, where the software generate a full report of all segments measured.