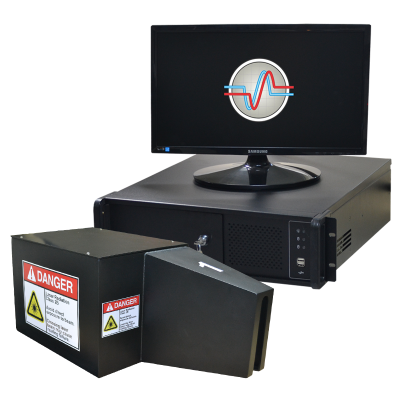

The Tozato Cut-to-Length Controller is an in-line and non-contact measuring system that provides high cut-to-length accuracy. Therefore, it results in better control of casting products such as billets, bloom, beam blanks and slabs. The system is designed to eliminate common problems caused by limit switch mechanical detectors such as lack of accuracy as well as to increase the operator’s safety. Also, it solves often problems of traditional wheel measurement methods that uses encoder, such as slippage, wobbles, wheel diameter wear or deformation and its constant maintenance.

In addition, the Cut-to-Length Controller measures absolute distances up to 492 ft. without contact due to its most innovative laser sensor technology. Thus, the Tozato Cut-to-Length Controller has a unique accuracy of 0.004 in for extremely hot surface up to 2192 °F and moving objects up to 33 ft/s casting speed.

READ MORE ABOUT TOZATO CUT-TO-LENGTH CONTROLLER

BENEFITS AND FEATURES

Through the use of this system, it is possible to:

FAQ (Frequent Asked Questions)

How is changed the length during the cut-to-length process?

The changes are made automatically through the integration of the CCM torch machine and the Tozato Cut-to-Length Controller software. Therefore, the production schedule is programmed, which make sure the production follow its schedule automatically according to what is desired.

What is the sensors working temperature?

Thanks to the Tozato Measurements wide experience and know-how in sensors cooling, even in the casting area, where the products reach temperatures over 800°C, the sensors temperature are kept around 40°C.

Why should I concern about decreasing the cut-to-length error tolerance?

After collecting the data from 3 different customers from Tozato, it is possible to have a real ideal on how important is to have a good cut-to-length control. Firstly, customer 1 had a cut-to-length variation of 40 mm, which accumulated in the end a metallic yield loss of 0.59%. Therefore, this represented an annual cost amount of 2.6 million dollars. Secondly, customer 2 had an average cut-to-length error of 25 mm, which summed up a metallic yield loss of 0.32%. By the end of the year, this customer was losing 1.5 million dollars. Finally, customer 3 had the same 25 mm of average cut-to-length error, but summed up 1.8 million dollars due to metallic yield loss.