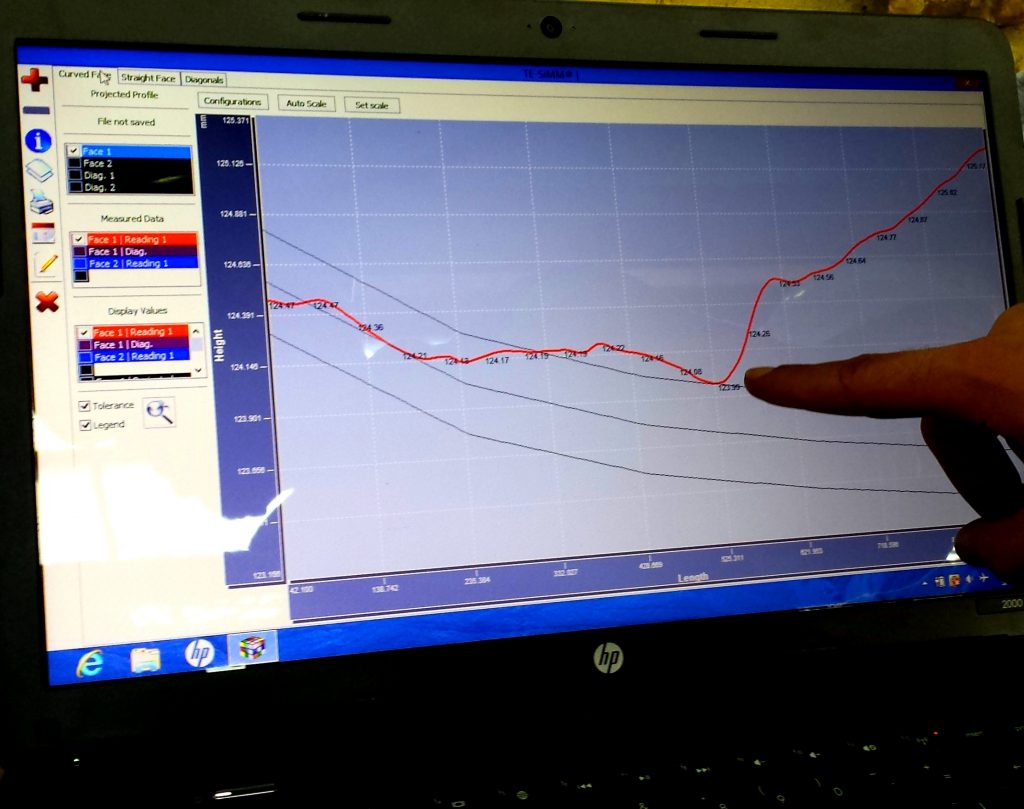

The Tozato Mold Profilometer is a system that measures the copper molds faces and diagonals cross-section profile, taper, wear, and deformity. It is composed of high precision and resolution contact sensors, monitored by a central processor and software that enables the correlation of the internal dimensions and position simultaneously. Extremely light, compact, and portable equipment, battery-operated, with accuracy of 0.02 mm and resolution of 0.01 mm.

READ MORE ABOUT TOZATO MOLD PROFILOMETER

BENEFITS AND FEATURES

Through the use of this system, it’s possible to:

FAQ (Frequent Asked Questions)

How long does it take to fully measure one mold?

The data gathering done with the Tozato Mould Profilometer is quick, safe and accurate. It is possible to perform all the measurements on the mould faces and diagonals within less that one minute.

Are there different system version for all kind of molds?

Yes. The Tozato Mould Profilometer is available on different versions for all kind of moulds, such as billets, blooms, beam blanks and slabs.

Is it possible to measure the mold assembled on the CCM?

Yes. However, the mould must be properly cleaned before performing the readings. Therefore, the mould must be free of debris in order to avoid any kind of alteration during the data gathering.