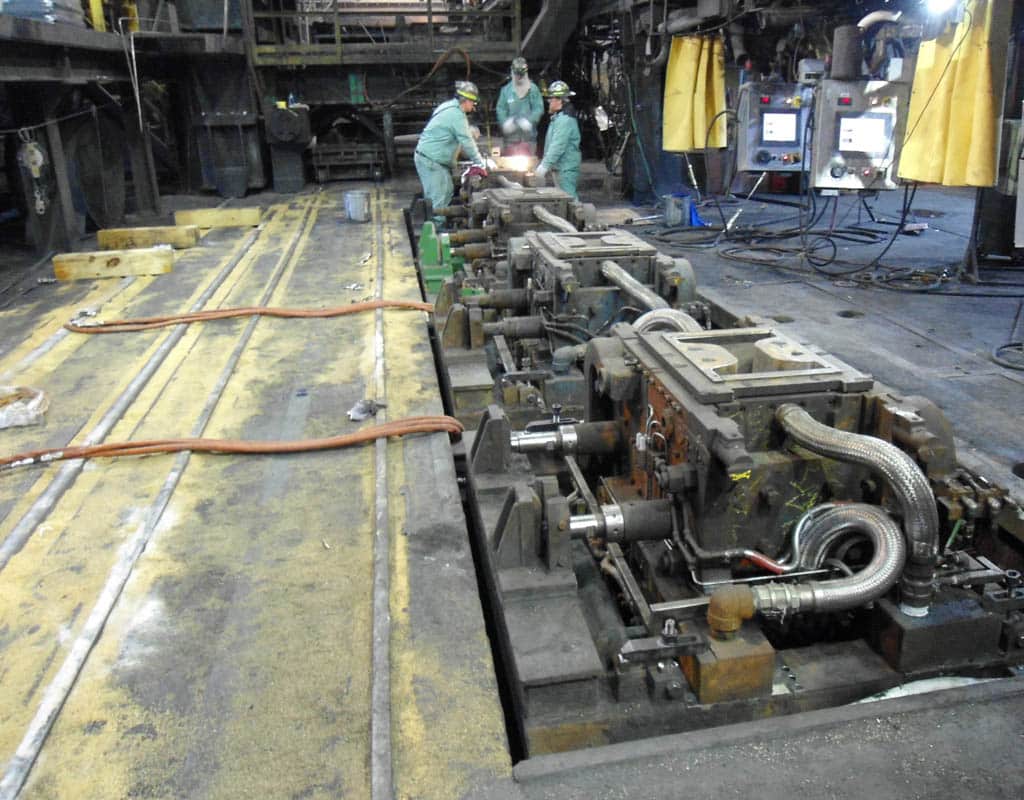

Oscillator topographic unleveling and mold service life time

It is rather common to have the copper molds with decreased service life due to early wear. The improper wear, among other reasons, is caused by intense friction between the product and the mold, therefore, resulting in trajectory errors offset caused by an oscillation table topographic unleveling.

After all, is there a straight relation between the oscillation table topographic leveling and the coper molds early wear? The study below will help you to understand how much these two factors are related.

Trajectory errors and mold wear: the correlation between these factors

During the continuous casting process, many factors may cause surface defects. However, two of them are very common and need special attention: oscillator’s trajectory errors and mold wear.

Nonetheless, it was not always possible to verify and prove the correlation between those two factors. With the advance of technology in oscillation monitoring, and in mold internal faces’ measurements, it was possible to prove this relation successfully. Find out more: