Surface and format defects caused by using wrong mold profile

Surface and format defects as well as breakouts may be caused by wrong mold profile and /or irregularities in the cooper mold profile. Knowing these failures is the very first step to prevent to become the next victim and accumulate losses. When it comes to such important part of steel making process, which is the CCM copper mold, some care and regular maintenance practices are of utmost importance to ensure its proper use.

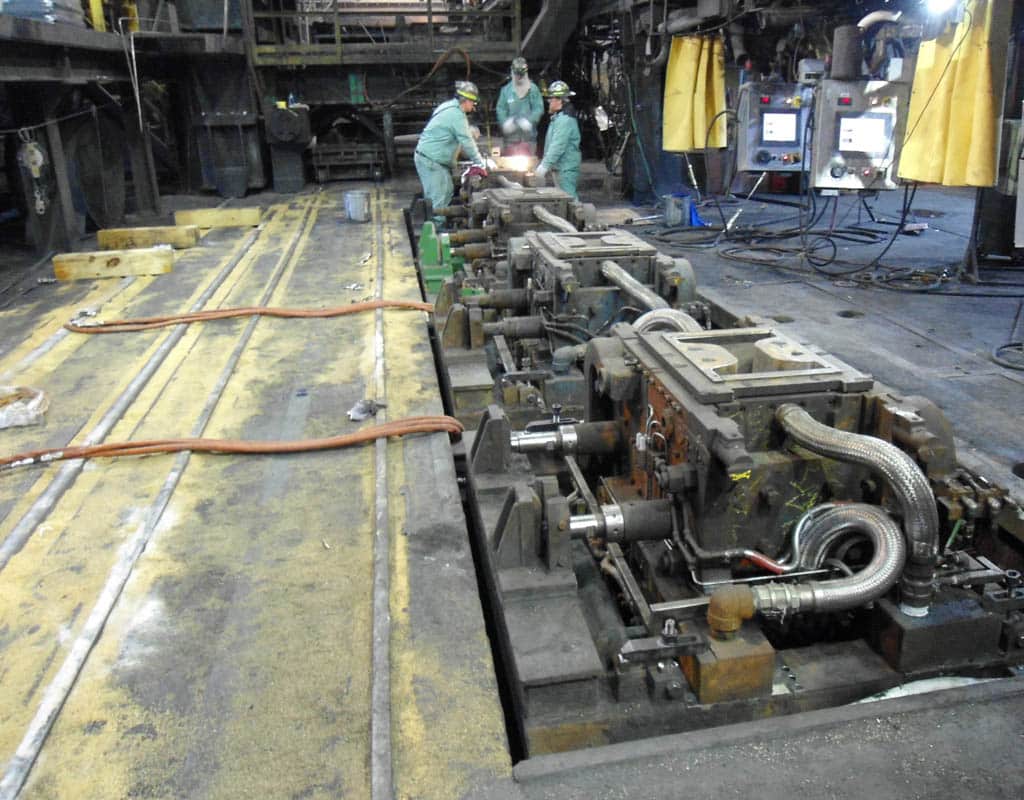

Oscillator topographic unleveling and mold service life time

It is rather common to have the copper molds with decreased service life due to early wear. The improper wear, among other reasons, is caused by intense friction between the product and the mold, therefore, resulting in trajectory errors offset caused by an oscillation table topographic unleveling.

After all, is there a straight relation between the oscillation table topographic leveling and the coper molds early wear? The study below will help you to understand how much these two factors are related.