The high friction level in continuous casting machine’s mold tubes strongly reduces their service life. A relation that can be proved by using appropriate tools to collect and analyze data.

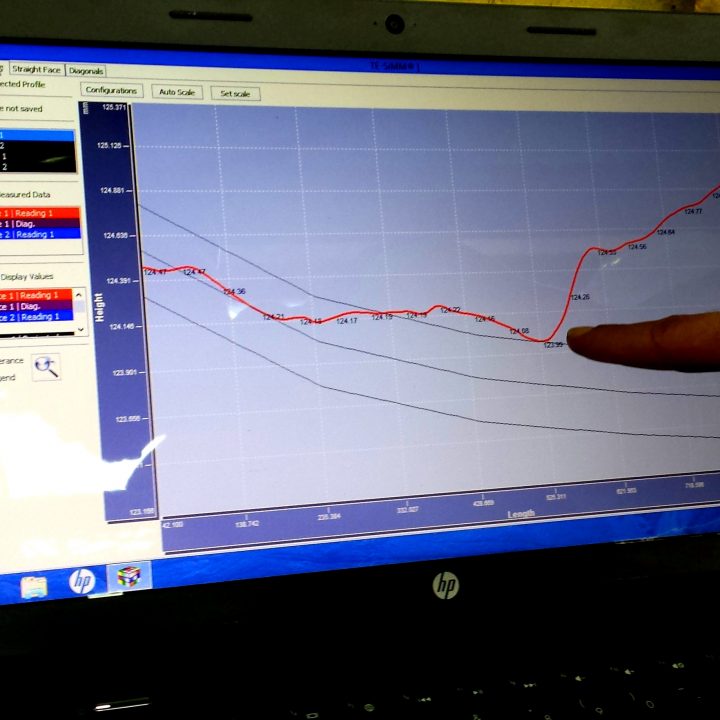

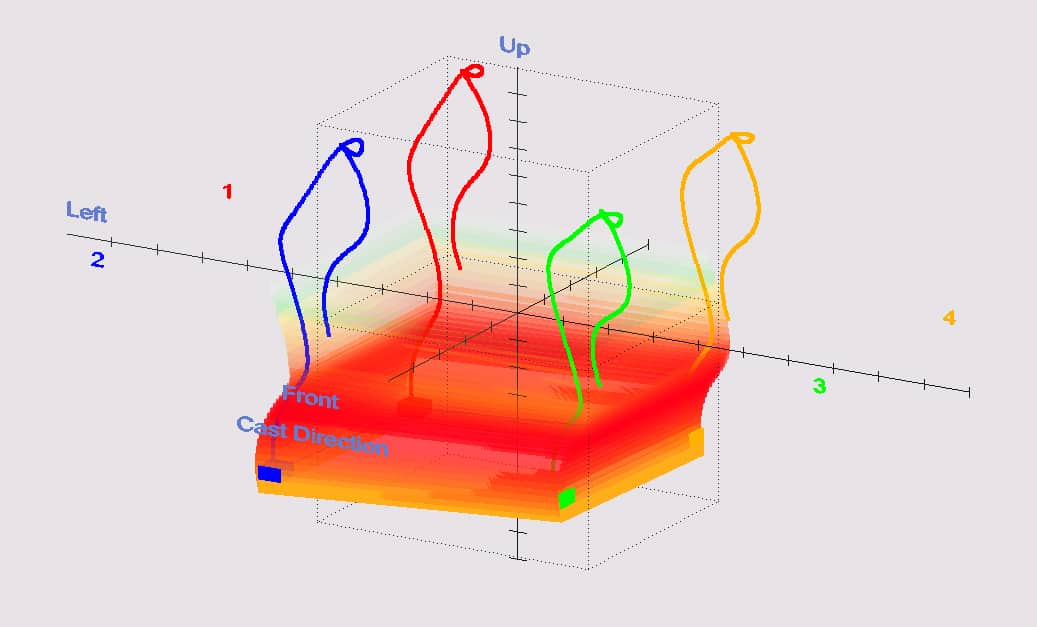

In order to acknowledge and prove the straight relation between friction and casting mold tubes early wear during the mold oscillation, it was performed a consultancy service using an oscillation monitor device on oscillators with molds presenting early wear.

Check below the research outcome.

Oscillators Friction

These molds presented considerable wear on their base and they were being disposed far below their estimated and desired service life.

After collecting the data, the mold presented wear at the same exact spot where friction was detected: at the mold base. In this case, the friction is the result of noticeable front-back displacement errors. To point out, a misalignment due to broken and loosen fixing bolts at the steady table, as well as broken springs, caused those errors during the mold oscillation.

Molds early wear

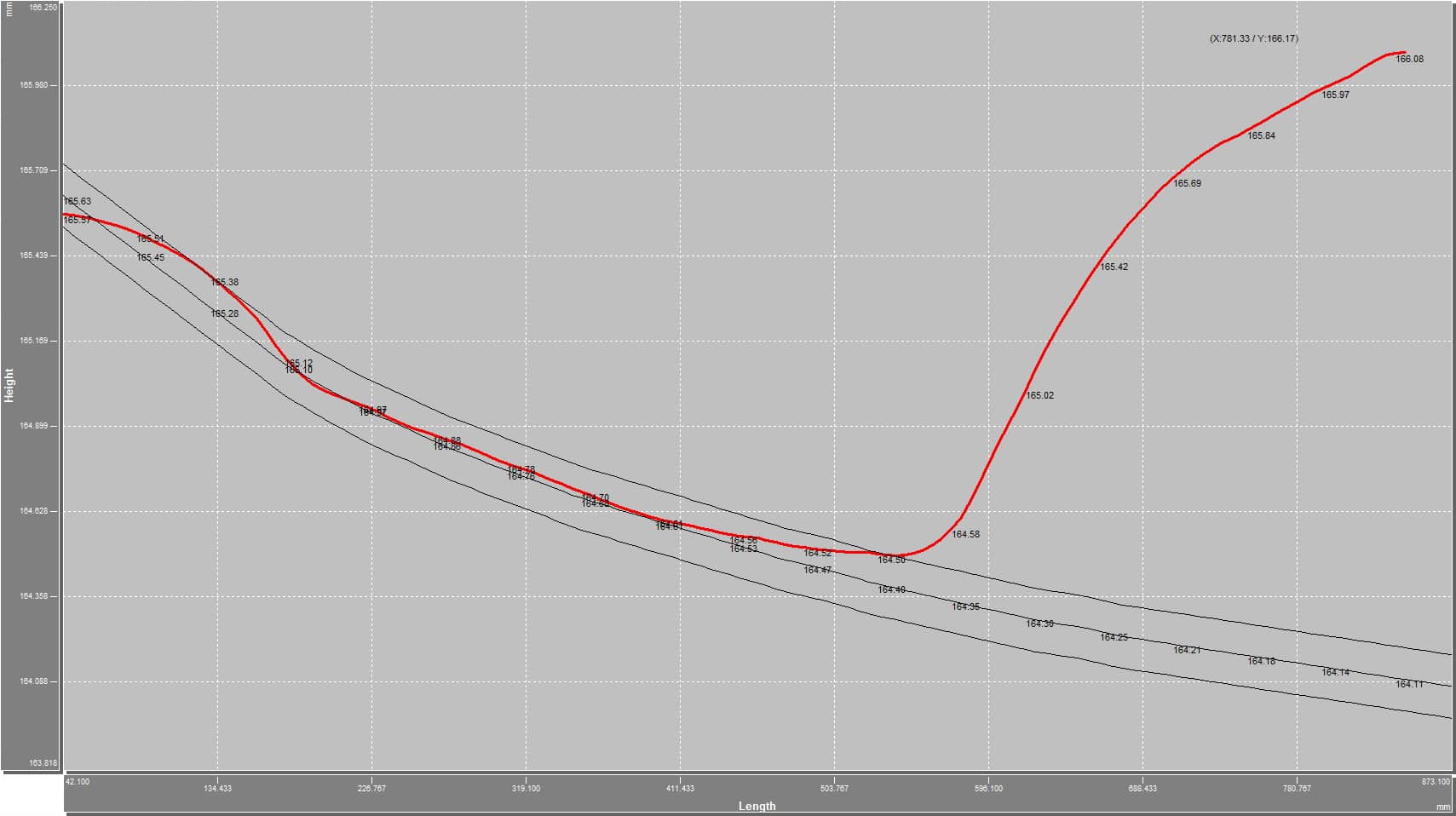

Once accomplished the data-collecting phase, a surveillance was performed on the molds internal walls using an accurate tool to measure the faces and cross section diagonals.

The final evaluation of the mold tubes wear showed some severe changes in the mold bottom inner part. In fact, both, mold oscillation analyses and mold wear surveillance, proved the same result: a high friction level at the mold base.

Upshot

In conclusion, it is noticeable that the spot of higher friction level is corresponding to the damaged part. A reliable and unbiased tool for mold checking turns to be an essential item for quality control, and in search for better production process control – characteristics shared among the greatest steel groups worldwide – to attend the needs and requirements of an increasingly demanding market.