Surface and format defects as well as breakouts may be caused by wrong mold profile and /or irregularities in the cooper mold profile. Knowing these failures is the very first step to prevent to become the next victim and accumulate losses. When it comes to such important part of steel making process, which is the CCM copper mold, some care and regular maintenance practices are of utmost importance to ensure its proper use.

The copper molds can be defined as the heart of steel making process and it also turns to be the most fragile victim from the stress carried out by the CCM, and therefore, causing several accidents and impairments to the process.

Additionally, having a wrong mold profile helps to produce a very thin and irregular shell, which may lead to several problems, such as corner and/or transversal cracks and double skin.

Corner Cracks

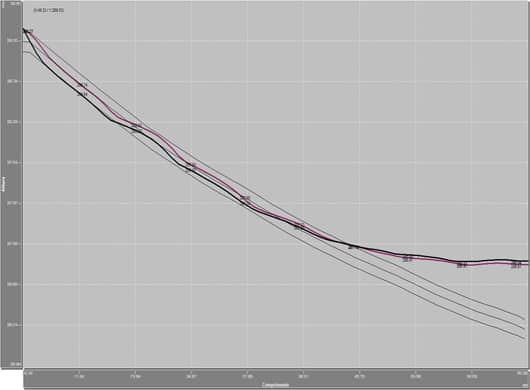

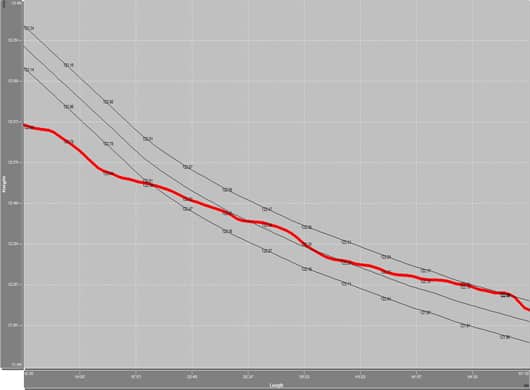

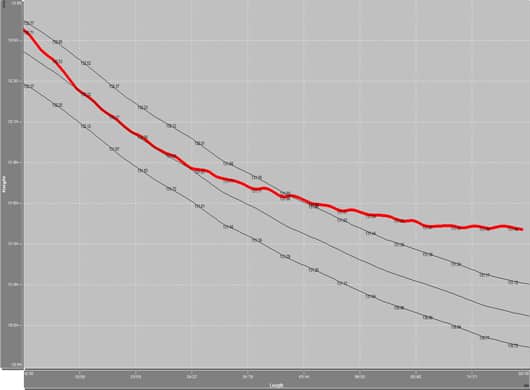

Normally found close (or very close) to the corner radius of the casting product, the corner cracks are associated to wrong mold profile radius problems, as well as other common profile errors caused by the wear. Moreover, wrong taper and misalignment between the mold and foot roll are also listed as some probable causes of corner cracks. Therefore, having control over the alignment and measure the mold profile on regular basis are important practices to prevent this defect from happening.

Double Skin

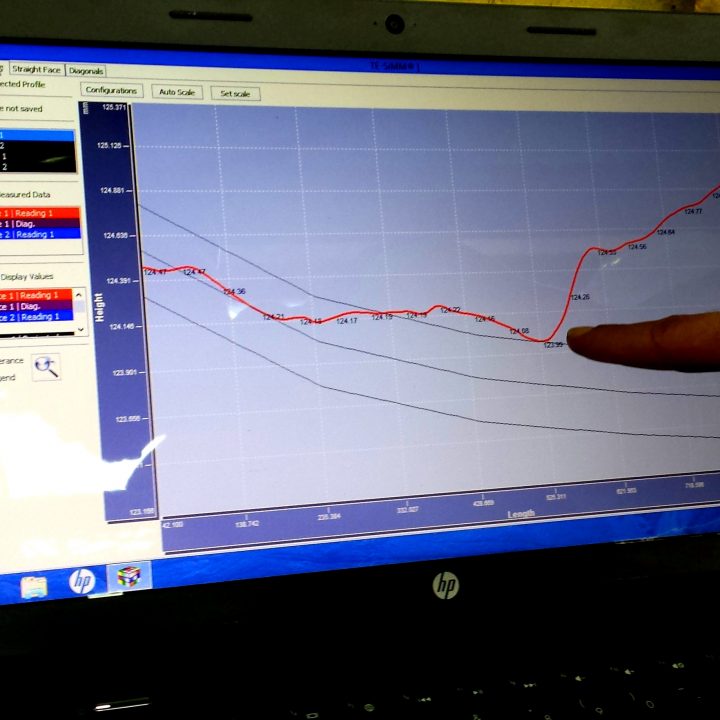

Double skin or laps are defects that generates superficial scales on casted products and it also can be known as irregular and gross oscillation marks. Additionally, double skin may lead to exfoliation and slivers during the hot rolling process and it is more than likely to occur when there is wear or even cracks in the copper mold meniscus area used at the continuous casting machine.

Transversal Cracks

Usually concentrated in the casted product corner radius, the transverse cracks can be found in the depth of oscillation marks in two types: transverse cracks with depression and transverse cracks with no surface deformation. Furthermore, the cracks opening size defines the problem severity level as light or severe.

The deformation in the mold meniscus, as well as its misalignment in relation to the foot rolls and its improper oscillation, are some of the most probable causes for this kind of defect. Hence, it is important to have control over the mold condition, by always checking its taper, deformation and wear.

UPSHOT

It is important to have regular maintenance procedures to prevent most of casting production defects. The regular mold profile measurement by using an accurate system for profile measurement is essential to prevent these problems from happening during the production process, and thus, avoiding impairments and unwanted accidents.

One comment

Thanks , I’ve just been looking for information about this subject for a

long time and yours is the best I’ve found out so far.

[…] wear and deformation are considered a critical abnormality which leads to serious problems in the product quality. The company needs proper tools in order to being able to prevent issues such as prematurely worn […]

[…] deformation is considered a critical abnormality which leads to serious problems in the product quality. The company needs proper tools in order to be able to prevent issues such as prematurely worn […]